In early October, group members Ezequiel Goldberg and Adriana Ghiozzi attended the second biannual DEMO Prospective Research and Development Workshop hosted by EPFL and organized by EUROfusion.

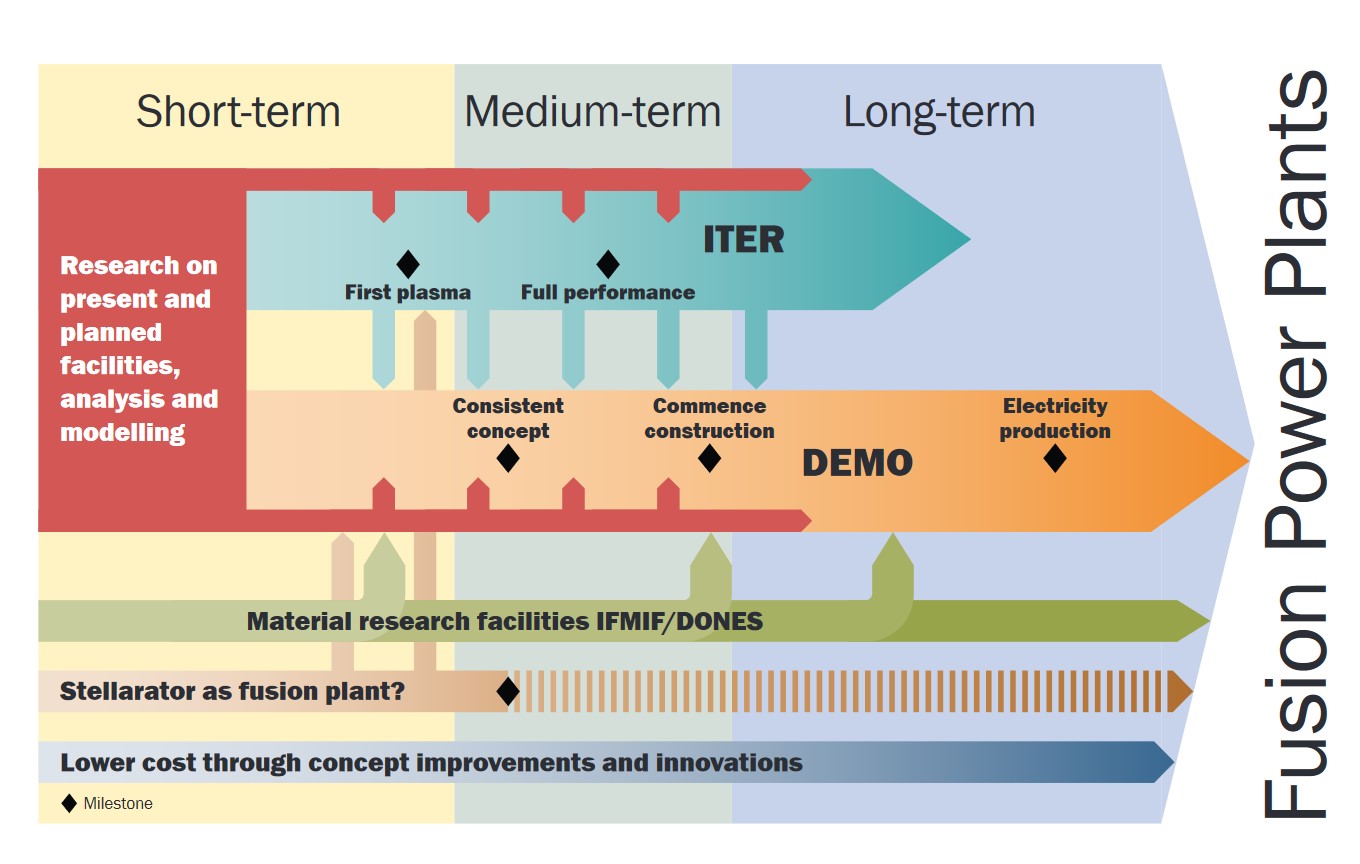

DEMO, or the DEMOnstration fusion power plant, refers to fusion devices to be developed post-ITER which, unlike ITER, will be connected to the electric grid and demonstrate net power production in a closed fuel cycle. Broadly, the goal of the workshop was to identify and discuss the current technical, engineering, and economic gaps between a DEMO device and a future fleet of fully-industrialized electricity-producing fusion devices.

As the guiding document for all EU fusion activities, the EUROfusion Roadmap identifies research and development for DEMO as a near-term priority to be carried out in parallel with the construction of ITER. In fact, completing an integrated design of the DEMO reactor is named as one of eight key missions in the first stage of the EUROfusion Roadmap, which is set to run through the remainder of the 2020s. The workshop is one of many EUROfusion activities being conducted in support of that mission.

The workshop consisted of two days of talks and discussion in a hybrid format, with some participants attending in person at EPFL and others connecting remotely via Zoom.

During day one, speakers took a deep dive into various technological opportunities within that gap, including advanced breeding blanket technology, liquid metal divertors, and a host of novel first wall and divertor materials. Day two, on the other hand, focused on the economic challenges facing the industrialization of fusion, including issues with supply chains and knowledge management.

EUROfusion has identified three different potential paths for commercialized fusion in the post-DEMO era, including a near-term pulsed tokamak scenario (similar to ITER and DEMO), a long-term steady-state tokamak scenario, and an advanced scenario (namely, a stellarator concept device). Each of these distinct conceptual directions presents a different set of technical challenges for which some workshop talks presented potential solutions.

As a whole, the talks painted an optimistic picture of innovations happening today with applications across the landscape of fusion technology – from improved neutral beam injection hardware to numerous approaches for extending the lifetime and efficacy of divertors.

The Fusion Group is grateful to the workshop organizers for facilitating a productive event, to the speakers for sharing their insights, and to fellow participants for stimulating lively discussion!