Radiation nearly always deteriorates the materials exposed to it, requiring replacement of key components in high-radiation environments such as nuclear reactors. But for certain alloys that could be used in fission or fusion reactors, the opposite turns out to be true: Researchers from MIT and Lawrence Berkeley National Laboratory have now found that instead of hastening the material’s degradation, radiation actually improves its resistance, potentially doubling the material’s useful lifetime. This finding came as a surprise to nuclear scientists and can be potentially used in new fusion reactors designs. The work lead by Weiyue Zhou and Prof. Michael Short have been recently published in Nature Communications.

Prof. Short says the finding was a bit of serendipity. In fact, the researchers were looking to quantify the opposite effect. Initially they wanted to determine how much radiation would increase the rate of corrosion in certain alloys of nickel and chromium that can be used as cladding for nuclear fuel assemblies. Right from the start, though, the tests showed signs of the opposite effect—corrosion, the main cause of materials failure in the harsh environment of a reactor vessel, seemed to be reduced rather than accelerated when it was bathed in radiation, in this case a high flux of protons. In the words of Prof. Short: “We repeated it dozens of times, with different conditions, and every time we got the same results” showing delayed corrosion.

The kind of reactor environment the team simulated in their experiments involves the use of molten sodium, lithium, and potassium salt as a coolant for both the nuclear fuel rods in a fission reactor and the vacuum vessel surrounding a superhot, swirling plasma in a future fusion reactor. Where the hot molten salt is in contact with the metal, corrosion can take place rapidly, but with these nickel-chromium alloys they found that the corrosion took twice as long to develop when the material was bathed in radiation from a proton accelerator, producing a radiation environment similar to what would be found in the proposed reactors.

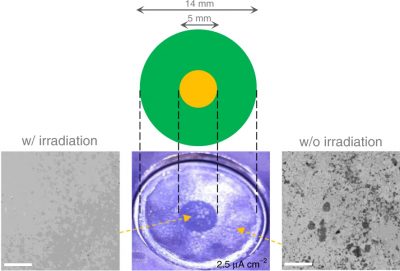

Careful analysis of images of the affected alloy surfaces using transmission electron microscopy (TEM), after irradiating the metal in contact with molten salt at 650 degrees Celsius, (a typical operating temperature for salt in such reactors), helped to reveal the mechanism causing the unexpected effect. The radiation tends to create more tiny defects in the structure of the alloy, and these defects allow atoms of the metal to diffuse more easily, flowing in to quickly fill the voids that get created by the corrosive salt. In effect, the radiation damage promotes a sort of self-healing mechanism within the metal. There had been hints of such an effect a half-century ago, when experiments with an early experimental salt-cooled fission reactor showed lower than expected corrosion in its materials, but the reasons for that had remained a mystery until this new work.

Prof. Short highlighted that “Being able to more accurately predict the usable lifetime of critical reactor components could reduce the need for preemptive, early replacement of parts.” Also, “the discovery could be relevant for a variety of proposed new designs for reactors that could be safer and more efficient than existing designs.” The findings could also be useful for several proposed designs for new kinds of fusion reactors being actively pursued by startup companies, which hold the potential for providing electricity with no greenhouse gas emissions and far less radioactive waste.

Source: phys.org