The third coil in a series of High-Temperature Superconducting (HTS) coils known as ‘little big coils’ (LBC) has enabled the highest direct-current magnetic field to date at the National High Magnetic Field Laboratory (MagLab), United States. This last coil which barely weighs 400 grams generated a field of 14.4 T while able to retain the superconducting state in a background field of 31.1 T created by a resistive magnet, thus reaching the highest field ever registered of 45.5 T.

To put this figure into context, bear in mind that the Earth’s magnetic field ranges from 25 to 65 uT on its surface, a hospital MRI magnet reaches around 2 or 3 T, and the current NbTi main dipoles installed in the Large Hadron Collider operate at 8.4 T.

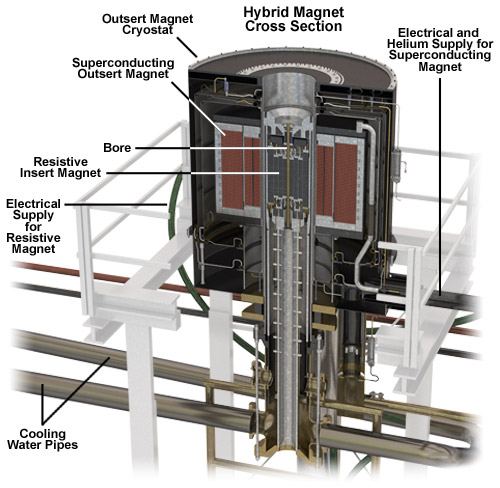

The outstanding field exceeds by 0.5 T what has been the strongest magnetic field for almost 20 years, also produced by a MagLab’s magnet, but based on Nb3Sn, a Low-Temperature Superconducting niobium alloy. It is important to highlight that in both cases the magnets are hybrid, meaning that resistive (commonly using copper and silver) and superconducting coils are put together in order to produce such strong fields. The main difference is that, in the 45.5 T magnet, the background field is generated by the resistive magnet with the HTS one inside, where in the 45 T magnet the Nb3Sn coil is outside generating the background field (see the picture below).

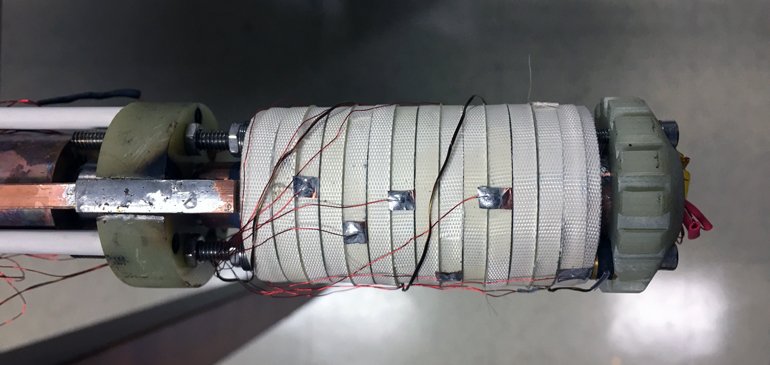

The LBC series rely on the HTS composite REBCO (REBa2Cu3Ox, where RE stands for a Rare Earth: Yttrium or Gadolinium) available in the form of 12 mm wide thin tapes. The tape is composed of a 30 um thick Hastelloy substrate that provides mechanical stability, the 1.5 um thick superconducting REBCO layer, and 5 um of copper to stabilize the conductor against heat deposition and quench. One relevant feature in the LBC coil is the lack of insulation in its construction, which results in weight and bulk reduction, and allows the current to bypass any resistive region found along the winding. This has been crucial in order to dramatically reduce the amount of stabilizing copper in the tapes as the electrical burn-out observed in insulated HTS coils is removed.

The potential increase in magnetic field when using REBCO tapes is even higher, but flaws introduced in some of the tape edges during the slitting of REBCO tapes substantially reduced the superconducting capabilities. The tests carried out at MagLab have served to identify some of the problems arising during the manufacturing process and will help in the improvement of the incipient HTS Technology, motivated by the need of strong magnetic fields in several fields, such as Medicine (magnetic resonance imaging), High Energy Physics (particle accelerators), and Fusion (fusion reactors by magnetic confinement), some of them with immediate impact on society.

Further details about this milestone in HTS Research can be found in the article published in the journal Nature. Moreover, we deeply recommend visiting the MagLab website to those interested in knowing more about magnet Technology.